Find out how to machine AR-15 upper components, from deciding upon the right aluminum alloy to employing proper CNC milling techniques. Discover best practices for creating the hand rail–barrel interface with precision and durability.

AI can revolutionize numerous facets of your operations aside from the machining itself. Think about using algorithms to improve scheduling and resource allocation.

Complicated Functions: Geared up with Superior capabilities like live tooling, CNC lathes can execute milling, drilling, and tapping functions in addition to turning.

Waiting for 2025, Haas CNC machines are very well prepared to become key gamers Down the road of producing. AI, predictive upkeep, and smart manufacturing unit solutions’ integration is just not a pattern, but a must for maintaining with the tempo of the speedily modifying and more and more complex industry.

Resistance to alter: Let's be honest, people today don't always like change. You may encounter resistance from your workforce when seeking to put into practice AI.

Now, let's speak about how AI is stepping in and revolutionizing CNC machining. AI, as we know, is focused on earning machines intelligent. In CNC machining, AI is currently being used to reinforce precision, make improvements to efficiency, and decrease waste. Here are a few techniques AI is executing that:

To search Academia.edu and the broader World-wide-web more quickly and even more securely, please have a several seconds to update your browser.

AI functions as being a dynamic lover, examining variables such as product Homes, machining disorders, and preferred outcomes. This capability not merely broadens the operational alternatives but additionally makes it possible for engineers and machinists to examine innovative ways to elaborate tasks.

There are lots of providers harnessing the potential of AI in CNC machines. MachineMetrics has produced a platform for actual-time visualization of CNC machine analytics, leading to 20% increases in throughput and efficiency.

On the vanguard of this AI driven revolution are Haas CNC machines. AI integration into these machines is Portal expected to improve efficiency, reduce downtime and increase productivity Over-all.

The turrets on dual-spindle CNC turning centers have Software slots on both sides of the turret and might make much more advanced parts than These with one spindle. The Instrument (to the turret) is programmed to maneuver for the bar.

Device lifetime prediction is very important in CNC milling to improve machining functions and lower costs. This analyze explores the applying of synthetic neural networks (ANNs) for predicting Device daily life based upon machining parameters for instance RPM, feed pace, axial depth of Minimize, and radial depth of Minimize.

From prototype to very long-time period production, Hexagon has the procedures and infrastructure set up to provide your products along with all the certification and traceability needs needed.

With easy to use programming capabilities and customizable alternatives from which to choose, you'll be able to make certain that Every single system is personalized especially to your business' demands. Each individual machine undergoes demanding screening in MultiCams Dallas facility right before getting unveiled on to the market, so you know your investment pays dividends in precision performance.

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Anna Chlumsky Then & Now!

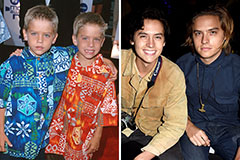

Anna Chlumsky Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!