Layout and Programming: Engineers start out the look stage by making use of CAD computer software to build a 3D model of their ideal element. Immediately after ending this step, engineers transform this file to CNC-appropriate format right before sending it off for plotting on CAM software package, exactly where paths with the machining tools will probably be marked out prior to remaining uploaded immediately onto a CNC machine.

Cutting tools are of various dimensions and styles In line with the requirements. The followings are classified as the common samples of milling cutters.

As a result of its automated higher-precision procedures, CNC machining parts proceed to remodel industries from aerospace to health-related devices.

Within the 2030s, work stores will most likely go on to evolve with progress in CNC technology, which includes automation and wise manufacturing. These improvements will permit work outlets to supply even quicker plus more efficient companies, retaining their competitive edge out there.

In combination with becoming a superb immediate manufacturing procedure, CNC machining is undoubtedly an indirect manufacturing course of action to assist processes like injection molding.

Limited tolerances are the first rationale to implement CNC precision machining. Tolerance is also known as dimensional precision. It refers to the slight deviation in the size of a machined part from its CAD blueprints.

CNC machining is very little in need of a miracle for companies, furnishing large-velocity manufacturing with comprehensive automation and ultra-high precision. The plenty of advantages of the CNC machining course of action have designed it relevant in many manufacturing industries.

*There might be discrepancies concerning the data demonstrated and the actual values, This could be confirmed through the sales consultant.

The freshly made missile, capable of carrying a number of nuclear warheads, was demonstrated during an Oct army work out that simulated a retaliatory nuclear strike.

Several machine retailers will inquire in the outset if the customer requires precision machining, as this normally implies that the RfQ demands more thought. Otherwise, then the requirement for precision machining might be indicated simply by like tolerances.

Material expenditures may be reduced by thinking about the scale of your blank required, and the associated fee and machinability of the bulk content (softer alloys are speedier to machine).

Nanotech Precision, LLC is about micro component machining, And that's why we concentrate on little and micro-sized Swiss turning and Swiss machining. Having an industry development towards miniaturization, Nanotech Precision has developed tested capabilities to Swiss machine the smallest elements with a greater degree of precision and consistency. Nanotech Precision makes use of Swiss turning machine tools created for Intense rigidity and course of action security. Approach security is vital in machining medical components, aerospace elements, or any time a high degree of accuracy and repeatability is necessary.

The massive-scale manufacturing course of action for boats and also other water transportation demands automation to satisfy the manufacturing deadlines and quality Command. That is only probable with CNC machining.

CNC has totally changed just how tooling has made. CNC technology has paved how for custom-designed dies and here molds which will build any type and condition of solutions.

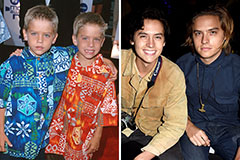

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Michael C. Maronna Then & Now!

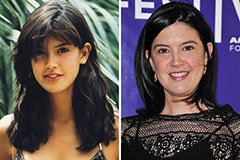

Michael C. Maronna Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now!